Our product development service

Fully integrated solutions – from first concept through to serial production, from small numbers to tens of thousands to many millions of parts, we work alongside our customers as a reliable development partner and dependable manufacturer of high quality products.

From concept to serial production

1. Concept development

- Demand analysis

- Creating solution concepts

- DFM (Design for Manufacture)

2. Product specification

- Drawings and 3D modeling

- Critical criteria definition

- Product testing

3. Feasibility analysis

- FEA simulation

- Manufacturing feasibility

- Tool design models

- Supply chain considerations

4. Concept validation

- Material evaluation

- Prototyping and sampling

5. Testing and validation

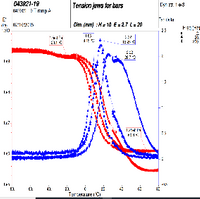

- Material properties

- Functional product testing

- Pre-serial trials

6. Industrialization

- Construction of molding and demolding tools and automated handling units

- Finalization of serial process

- Part and material validation package to suit customer requirements

- Process audit